Digitalization - A key enabler to fast-tracking the reduction of indirect emissions throughout the supply chain

Posted

Mar 1, 2021

Introduction

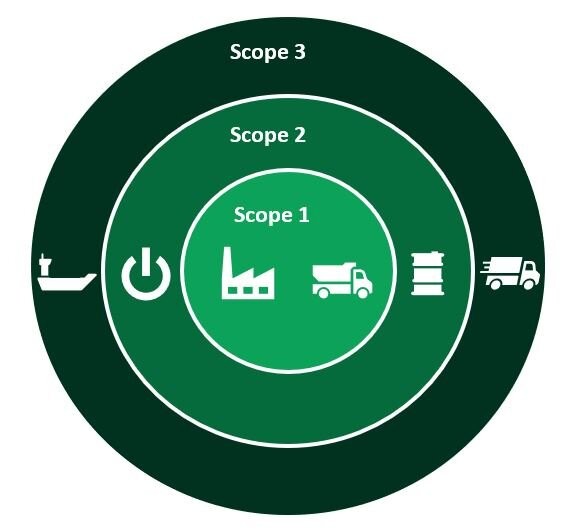

Until recent times; industry focus, regulatory drive, and corporate agenda has been geared towards reducing what are defined as - Scope 1 and Scope 2 emissions. Scope 1 describes direct emissions from owned or controlled assets, with Scope 2 describing the indirect emissions of purchased energy.

With mounting pressure on all industries to reduce carbon footprints, there is an increasing shift driven by end-consumers and stakeholders for industrial companies to encompass the indirect emissions that occur throughout the value chain (upstream and downstream) into their green agendas.

These indirect emissions are what are known as Scope 3. And Scope 3 emissions hold massive potential for industrial companies to identify hotspots and multiply their decarbonization efforts across the supply chain.

Fig 1. Illustration of Scope 1-3 emissions throughout the value chain

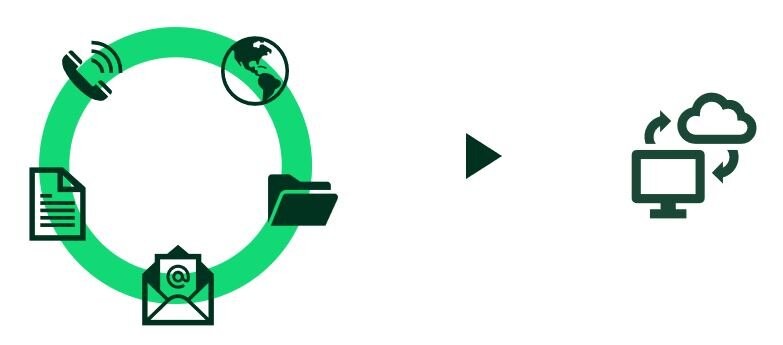

First and foremost, for any industrial company to consider changing anything in their supply chains they first need to be able to measure what it is they want to change. And to the lay the groundwork for that, a good visual representation of the supply chain is needed.

To manage indirect emissions this needs to include a way of accurately reporting the carbon sources and quantities; not just for auditing purposes, but as a means of using that insight to adjust and improve.

The purpose of this article is to highlight some of the challenges faced today and how increased computing power is making it possible to start working towards this goal.

The ability to measure emissions throughout the entire value chain is the first step towards creating greener supply chains

Technologically speaking, consider the changes the world has seen in the past ten years alone. Consider the data and availability of information that exists throughout the production process of supply chains today.

In smelters and refineries, sensors can provide near real-time data. Industry 4.0 has allowed manufacturers to monitor digital replicas (known as the Digital Twin) of assets used production processes and create global visibility. This forms a solid foundation for improved decision making.

"A key enabler of this digital age has been the access to computing power and the democratization of that power through cloud services."

On the transportation side of the supply chain the ability to track the location of raw materials at any given moment through satellite data (i.e. AIS) is another luxury that that did not exist ten years ago.

A key enabler of this digital age has been the access to computing power and the democratization of that power through cloud services. The calculation and processing of massive amounts of data can be done today using advanced algorithms that was simply not possible 20-30 years ago.

These are digital enablers of change to welcome and celebrate; but, at the end of the day, creating greener supply chains depends on the ability to put these enablers into action.

Drivers and motivation

Costs and revenue have always been key drivers for digitalization and optimization of any business activity. The same can be said as a central driver to the environmental agenda; however, one of the biggest challenges today when it comes to the proactive reduction of indirect emissions is lack of regulatory agenda.

Since many industries are not yet at a level where a price has been put on emissions, there are few economic incentives to drive the necessary change. Any given charterer, be it a smelter or refinery, is unlikely carry the full burden of transportation costs when it comes to moving from today’s environmental footprint to a carbon neutral footprint.

“Today, consumers are playing a substantial role in driving the agenda for change.”

This therefore needs to be a joint effort and it needs to be regulated. The big question is when will regulatory bodies agree, and a potential carbon tax come into effect? And can the world really afford to wait for it to happen? The industry leaders have great potential to take ownership of this agenda.

For example, it could be a valid choice when negotiating freight, the willingness to pay for the environment could be as commonplace as agreeing which party will carry the costs of vessel waiting time.

Today, consumers are playing a substantial role in driving the agenda for change. It is, however, important to note that there are many praiseworthy initiatives in play today, such as how industries have seen companies join forces to publish their scientific targets around emissions.

One noteworthy example of action is the Sea Cargo Charter, an initiative involving some of the world’s largest energy, agriculture, mining, and commodity trading companies together with a handful of shipowners/operators.

The Sea Cargo Charter will set a new benchmark for responsible shipping, transparent climate reporting, and improved decision making in line with the United Nations decarbonization targets (learn more about the Sea Cargo Initiative here).

While such initiatives are welcome and to be applauded, there is still a long way to go. Many industries have made huge leaps on the production side; and are now, with the technology available, better positioned than ever to consider the extent of indirect emissions and be ready to deliver on all aspects of the supply chain.

Visibility is foundational to any supply chain analysis

At the very foundation of this change is improving supply chain transparency and achieving end-to-end visibility. Without the ability to measure indirect emissions it is difficult to pin-point supply chain waste and take the necessary action. And the ability to measure starts with visibility.

Consider any industry - be it metals, power generation, cement, food production to name a few – then consider the number of business units and stakeholders involved (internally and externally) to ensure the end-product reaches the consumer. To better predict and manage the uncertainty that lives throughout this supply chain, these industries needs to start moving away from manual processes, silo-based sources of information, and segregated workflows.

The future needs to become data-driven, centered around one version of the truth, and facilitate collaboration among stakeholders internally and externally. Without building those foundations first, most individual companies will have a steeper climb when building resilient, decarbonized, and cost-effective supply chains while hoping to remain competitive.

The perfect world of the supply chain will never exist. There will always be some degree of uncertainty and risk due to circumstances beyond human control, as the events of 2020 have demonstrated.

But, to react and move towards proactive change for the better, improving visibility is the starting point.

A global opportunity for industry

Technology can form the foundations by enabling tracking, optimization, and facilitating the reduction of indirect emissions associated with the supply chain. The challenge facing many industries today is the lack of standards.

The intentions of moving towards carbon neutral or even carbon positive supply chains are no doubt widespread. Fortunately, the world does not have to wait for regulators to agree and force industries to move forward. With visibility throughout the supply chain, it can be done today. Most companies just need the right tools to do it

“Many industry leaders have great potential and a significant opportunity to become leaders.”

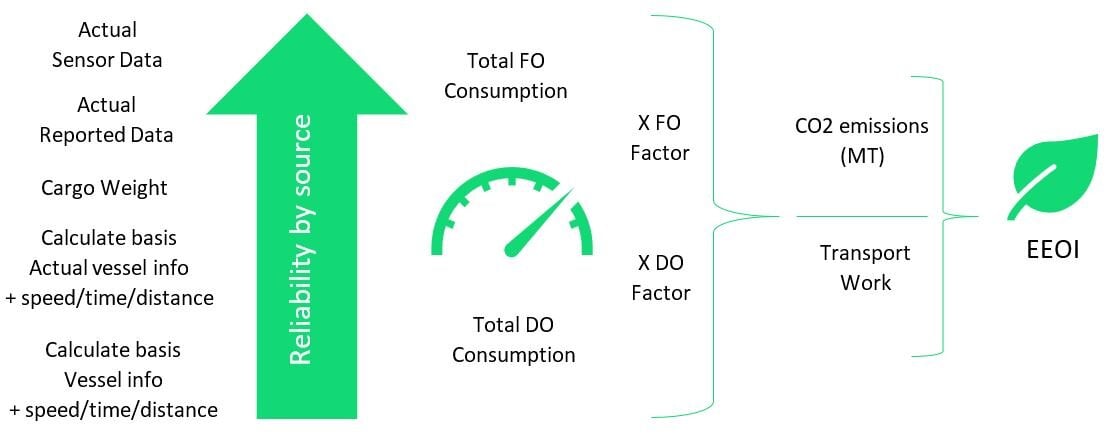

Calculation of EEOI (Energy Efficiency Operational Indicator) is a proven way of calculating Scope 3 emissions. However, a big challenge for stakeholders is to agree on is what should be used as the factors to accurately measure the consumption of carbon fuels to get to the end number.

Fig 2. Simplified illustration depicting EEOI calculation

To get there, most industries have the components at their disposal to calculate those figures. The question of what to track and what to calculate is up for debate, but with the level of information available today such as satellite data, sensor information, vessel information, and voyage specifics just to name a few; the pieces are there.

Consumer drive these industries is large and a force to be reckoned with, the power of that voice means that many industry leaders have great potential and a significant opportunity to become leaders.

The reduction of carbon emissions is continuously recognized as this generation’s biggest challenge. But through increasing visibility throughout their value chain by leveraging the power of modern tools and applications, industrial companies should see this an opportunity to get ahead and fast-track their own contributions.

Conclusion

To improve and reduce the carbon footprint of indirect emissions industries should start by first measuring and benchmarking emissions and use this data as a tool when planning and looking for optimization potential.

Such intel can then be turned into value in the decision-making process when nominating vendors, and considering not just where to source materials from; but what vessel types and under what speed should be used? What lot-sizes are optimal? Which shipowners should be used?

Although there are many initiatives aimed at zero emissions shipping, there is still a way to go. Until then, acceptance needs to be given to the fact that supply chains do (and will continue to) have emissions. But now is the time to explore how it can optimize, reduce, and identify the opportunities for continuous improvements until the common goal of carbon neutral is achieved.

Fig 3. Illustration of EEOI capture in modern applications